Contract manufacturing by TXCube

TXCube founders, through their career and professional experience, have developed a strong collaboration with component manufacturers, contract manufacturing companies, drawing part manufacturers and tooling companies. These companies are mainly located in Europe or Asia.

TXCube provides its customers with its strong industrial networks in order to provide production services at best conditions of price, quality and lead time.

The most suitable industrial production model

TXCube adapts each industrial production and electronic manufacturing model to the product challenges and company stakes.

Does the product have special constraints? Does it have to be manufactured in Europe for reasons of proximity to its market? Does it have to be called “Made in Europe”? Does it have strong constraints in terms of cost, material or high labour? Or a very tight schedule? Depending on the answers to these essential questions, TXCube will be able to offer either local production services from French or European partners, or manufacturing solutions in China, where a TXCube team is based.

TXCube will also be able to offer a so-called hybrid industrial production with supplies of some parts and sub-assemblies from Asia and other supplies from France or Europe then a final assembly, test and final packaging made in France/Europe. Purpose is to take advantage of the best of both worlds.

The most suitable production services

The choice of the industrial production plant for the finished product is key in the success of a project. It is based on many criteria.

For our industrial manufacturing plants, we select the most suitable industrial subcontractor depending on the complexity of production services to be delivered, the eco-system of subcontractors and suppliers nearby, the skills of the local teams, the production capacity in place, and the capacity to deploy the test solutions to ensure the required quality level. We also assure our customers the confidentiality of their projects and industrial means put in place to protect the intellectual property of their products.

The means of production are auditable by our customers if they wish.

Tooling and quality control in production

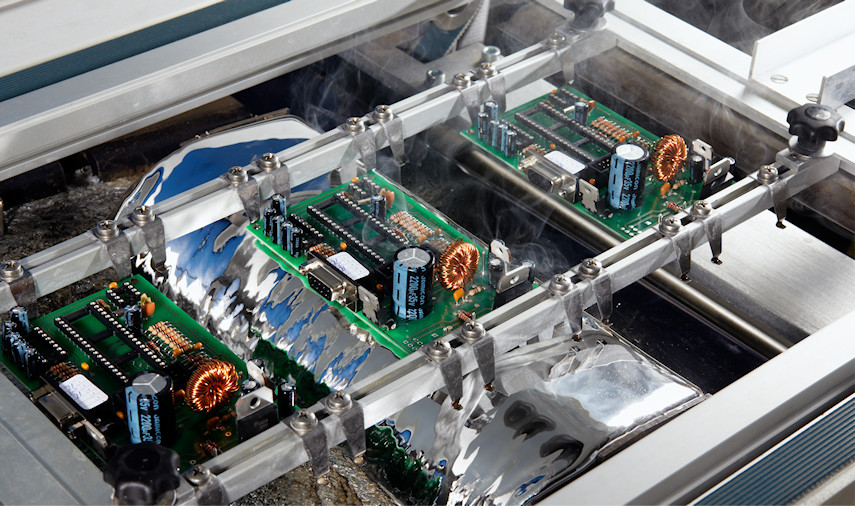

In order to increase productivity, we develop the most suitable tools to produce products in a repeatable way. This approach helps smooth and facilitate the assembly of products.

Our teams of industrial engineers have the skills, experience and expertise to carry out these operations with great efficiency. We also develop test methods and write product manufacturing procedures during the study and preproduction phase. Each manufacturing step is detailed and challenged to reach the best yield at the end of the production line and a consistent product quality over time and at each production batch. Our teams draft the incoming inspection tables for purchased products and components as well as the quality control tables for finished products. We also manage the traceability of products according to the expressed needs, the labelling of packages and transport cartons.

Got a project ?

TXCube brings the experience on the best way to meet your challenges. So, don’t wait and