Prototypes

Industrial prototyping occurs at different stages of a project, using different technologies. TXCube supports customers in these key project milestones through its expertise in product development and industrialization.

We can advise, as needed, on the right technologies to implement for the prototype manufacturing.

TXCube also helps customers to define and perform tests (functional or endurance) in this prototype development phase in relation to the product specifications.

Several prototype phases

Each prototyping phase is validated to confirm design choices before moving to the next step of the project.

The need for prototypes occurs in the following phases:

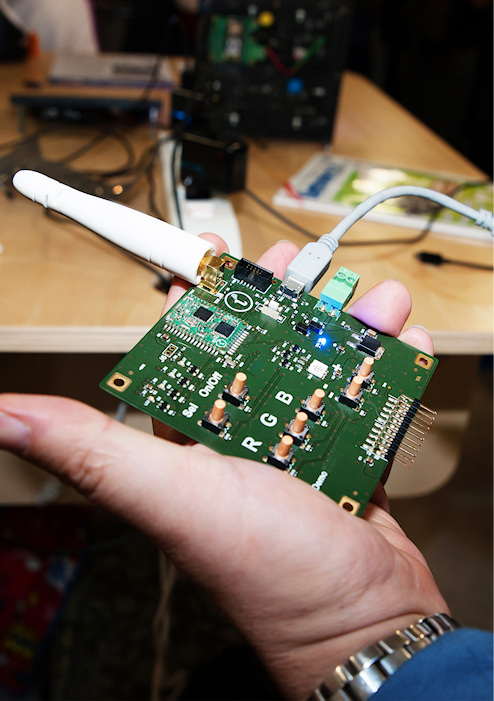

POC (Proof Of Concept) is an early prototype also called mock-up. It demonstrates the functionality of the concept. It can be made based on an electronic development board for the electronic prototypes and 3D printings made from drawings for the mechanical prototypes.

EVT (Engineering Validation Test) is a first product prototype that looks like the final product. It allows to conduct the first validation tests of the product. It is based on prototype manufacturing processes such as 3D prototyping.

DVT (Design Validation Test) is a fully representative prototype of the final product. It allows the complete validation of the product (validation of the specifications).

PVT (Process Validation Test) is also an industrial prototype representative of the final product allowing the complete validation of the product and manufacturing processes. It is produced with the toolings and test equipment used in mass production. This step is also called pre-series.

Mechanical prototype technologies

For mechanical prototyping devices, a large network of qualified suppliers helps TXCube to process all kind of mechanical parts. Depending on the tests to be carried out, TXCube advises customers on the right process choices.

For example, when performing functional or endurance tests, the process for creating a plastic part will not be the same.

The list below shows the prototype technologies we are regularly using:

- Plastic parts: Stereolithography (SLA), Selective Laser Sintering (SLS), Reaction Injection Molding (RIM), machining, etc.

- Metal parts: machining, laser cutting, folding, etc.

- Silicone parts: compression.

- Other specific drawing parts: cables, batteries, screens, etc.

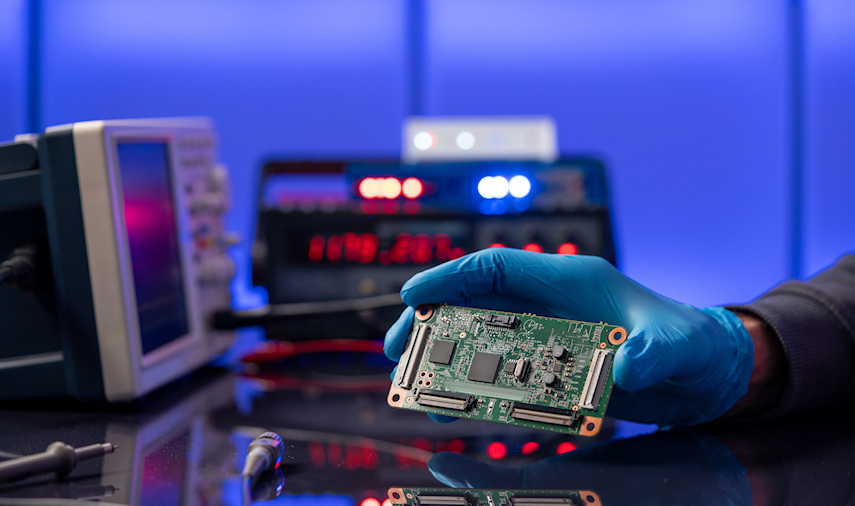

Electronic prototypes technologies

For electronic prototyping, TXCube relies on a network of qualified subcontractors to produce electronic boards (PCBA) representative of mass production. Often, the boards of the electronic prototypes are manufactured at the final production site in order to pre-validate the assembly processes of the boards and qualify the proposed second sources of components.

For PCBs, we address all kind of materials (FR4, IMS, etc.) and all types of complexities (single layer to multi layers: 16 to 24 layers PCB). Prototype PCBs are often produced with the industrial partners selected for the mass production stage. This allows TXCube and customers to approve supplier sources early in the project. The sourcing of components is taken into consideration from the design phase. TXCube advises components with strong market availability that allows an easy purchase for the prototyping of electronic boards and facilitate the supply in mass production phase.

Electronic prototypes assembly and testing

Following the purchase of parts and production of electronic boards, TXCube takes over the assembly, testing and delivery of functional prototypes. Based on our know-how, we have developed a method for validating products that allows us to ensure the compliance with the specifications.

This step begins with a check of the fully assembled product. To avoid late re-designs, we consider the «Design for Assembly» from the prototype phase. Specific toolings can be developed at this stage to guarantee and improve the assembly. After assembly, the tests are carried out to validate each requirement of the specifications (consumption, mechanical and climatic performances, validation of MMI, RF, etc.). Our customers can focus on marketing and promoting their product while we care about the development, manufacturing and supply chain.

Got a project ?

TXCube brings the experience on the best way to meet your challenges. So, don’t wait and