Product certifications: CE, UL, FCC, UKCA...

Prior to a product’s mass production, there is a significant and mandatory phase that can compromise the “Go to Market”. This is the product certification phase.

Each country has rules and standards to follow before allowing the importation of a product into its territory: CE marking or certification for the importation of products in Europe, UL certification for the United States, UKCA certification for the United Kingdom, etc.

We must add electromagnetic compatibility certifications for communicating electronic products such as EMC certifications in Europe and FCC certifications in North America.

This phase is mandatory to obtain a certified product and be able to sell it in the territories to which the certification relates.

Product certification starts during design phase

It is important to define the marketing countries of your product from the start of the project so that certain constraints are taken into account when designing it. The standards to be respected also depend on the purpose of the product (product for kids or medical product, for example), its on-board technologies (on-board radio and communication links), its type of power supply (battery or mains), the safety of use (electrical safety for example), or its resistance to the environment (ESD or electromagnetic tests).

These standards may also differ from one country to another. As an example, the standards for products connected to cellular networks (2G to 5G) are much stricter in the USA than in Europe. It is essential, when designing, to take into account the countries and their specificities.

It is also essential to provide for product qualification tests to be carried out in the pre-production phase in order to remove any doubt about a characteristic and avoid a refusal of product certification which would require a redesign of the product, the need to re-certify and a significant delay in marketing.

Certified laboratory

Product certifications are carried out at certified laboratories that are authorized to issue reports accepted by the countries for which these certifications are launched. We support our clients in this phase and ensure follow-up with the relevant laboratories. In fact, these laboratories must be provided with the entire design file, and sometimes with very specific elements they need to be able to test and award the precious sesame that certification is.

Products sent to laboratories are those from the pre-series or series phase. They must be similar to the products to be produced in mass production. A prototype cannot be sent to a laboratory for certification because it will not have the final materials and/or components of the production phase.

We work with laboratories able of certifying our customers’ products on all

continents with CE certification for Europe (also called CE Marking), UL certification and FCC certification for North America, and UKCA certification for the United Kingdom. Countries like Japan and South Korea also have their own certification standards that our partner laboratories are also able to pass on.

The product qualification phase

In order to avoid that the product certification is a sudden stop of the marketing of your product, it is necessary to anticipate this certification by upstream qualification phases during the industrialization of your product.

Certification has to be considered since the design stage.

It is essential to consider the reliability of the product as soon as the specifications are drafted. It must specify the constraints your product will face. Will it be exposed to the sun for hours? Immersed in water? Installed underground?

Think about operating time, impact resistance, temperature, sealing, standards, etc. Clearly define your needs and product constraints in your specifications. This will reduce the risk of re-design or overrun.

Also define the marketing countries. Certifications are expensive and require a lot of time and attention. Do not necessarily seek to certify the product at worldwide level but only on the countries where you will market it. On the other hand, a particular certification is always possible in target countries during a second phase of commercial development.

Product qualification testing is the verification that a product meets all the requirements of its intended use. This includes functional and non-functional tests.

Functional tests verify that the product is performing the intended function. Non-functional tests verify that the product meets all other requirements, such as safety, security and performance.

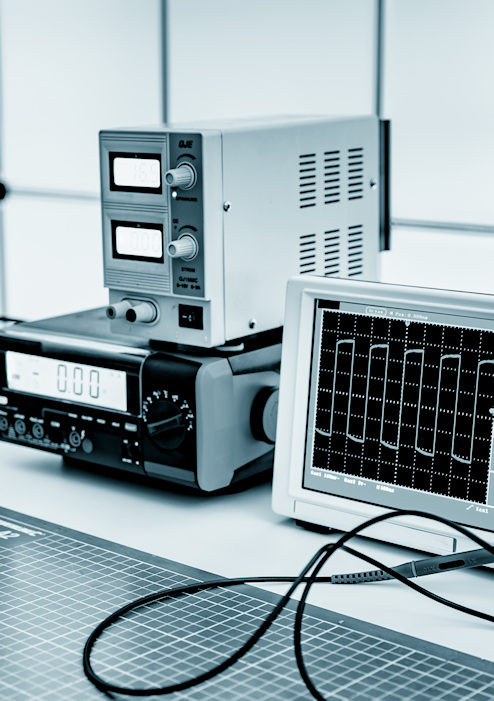

Regarding the subjects of electronic compatibility, if the design of the product is not fully mastered, it is always possible to qualify your product by doing a qualification or pre-certification at a laboratory equipped to test the electromagnetic emission which may disturb the electronic products or the electromagnetic susceptibility of the product to a source emitting alongside it.

Certification: a complex phase

Product certification is a complicated phase that must be prepared and thought out from the moment the product is designed, and then validated on all its points during the prototype and pre-series phases. A prior qualification may be necessary to avoid wasting a lot of time and money during this cutting phase. If you don’t have this experience, TXCube, with dozens of certified designs, can help you in this continuous monitoring of the performance of your product and then take care of all the exchanges with the certifying laboratories until obtaining the famous sesame opening you the doors of the desired geographic markets.

Got a project ?

TXCube brings the experience on the best way to meet your challenges. So, don’t wait and